PRODUCTS

Overview of Hastelloy G30 Hastelloy: Hastelloy G30 Hastelloy is a nickel-based high-temperature alloy composed of nickel, chromium, cobalt, tungsten and other elements, with a nickel content of approximately 37%. Hastelloy G30 is a nickel-based alloy with a high chromium content. It is more resistant to commercial phosphoric acid and the mixed environment of many highly oxidizing acid media such as nitric acid/hydrochloric acid, nitric acid/hydrofuric acid and sulfuric acid than most other nickel-based and iron-based alloys. Alloys have superior corrosion resistance. G30 alloy can prevent the formation of grain boundary precipitation in the welding heat affected zone, so its as-welded products are suitable for various chemical treatment engineering purposes.

chemical composition

Physical properties

Density: 8.22 g/cm3

Melting point: 1370-1400℃

Typical applications of Hastelloy G30 Hastelloy: widely used in phosphoric acid equipment, sulfuric acid equipment, nitric acid equipment, nuclear fuel reprocessing, nuclear waste treatment, pickling operations, petrochemical products, fertilizer production, pesticide production, and gold mine extraction. Hastelloy G30 has excellent resistance to hydrofluoric/nitric acid mixtures used in applications such as stainless steel pickling. Hastelloy G30 performs better in commercial phosphoric acid than other nickel- or iron-based alloys. Produce better resistance. Its use as an acid evaporator in the fertilizer industry is increasing day by day.

Comparison of corrosion resistance in commercial phosphoric acid: Comparison of the corrosion resistance of Hastelloy G30 Hastelloy, G alloy and 625 alloy in commercial phosphoric acid is as follows. The corrosion resistance of commercial phosphoric acid is determined by many factors, including concentration and temperature. , impurities and phosphate ore origin, etc. Corrosion rates for the same concentration of phosphoric acid produced from different phosphate mineral sources can vary widely. Therefore, corrosion tests were measured in phosphoric acid from different sources, and the corrosion resistance of G-30 alloy was expressed as a function of corrosion rate for G-alloy and 625 alloy respectively. In the acid with the same corrosion rate of 0.025-2.5mm, the corrosion resistance of G-30 alloy is usually 2-10 times stronger than G alloy and 265 alloy.

RECOMMENDED PRODUCTS

FAQ

Q: Are you a manufacturer or trading company?

A: We are a specialized manufacturer.

Q: How about the delivery terms?

A: 1. Payment: T/T, Western Union, Paypal, 30% deposit in advance and balance before delivery.

2. Min. Order Quantity: 100KG, or as required.

3. Transportation: By express (DHL,TNT,FedEx),air,sea,and train.

Q: How about discount?

A: Price is based on products and order quantity.

Q: Do you accept sample order?

A: Yes sure, please contact us for details.

Q: How about your after-sales service?

A: As a professional steel exporter, we offer promote technology support for all problems and questions.

Besides, we accept goods return or replace for quality problem.

Q: How does your company control the quality?

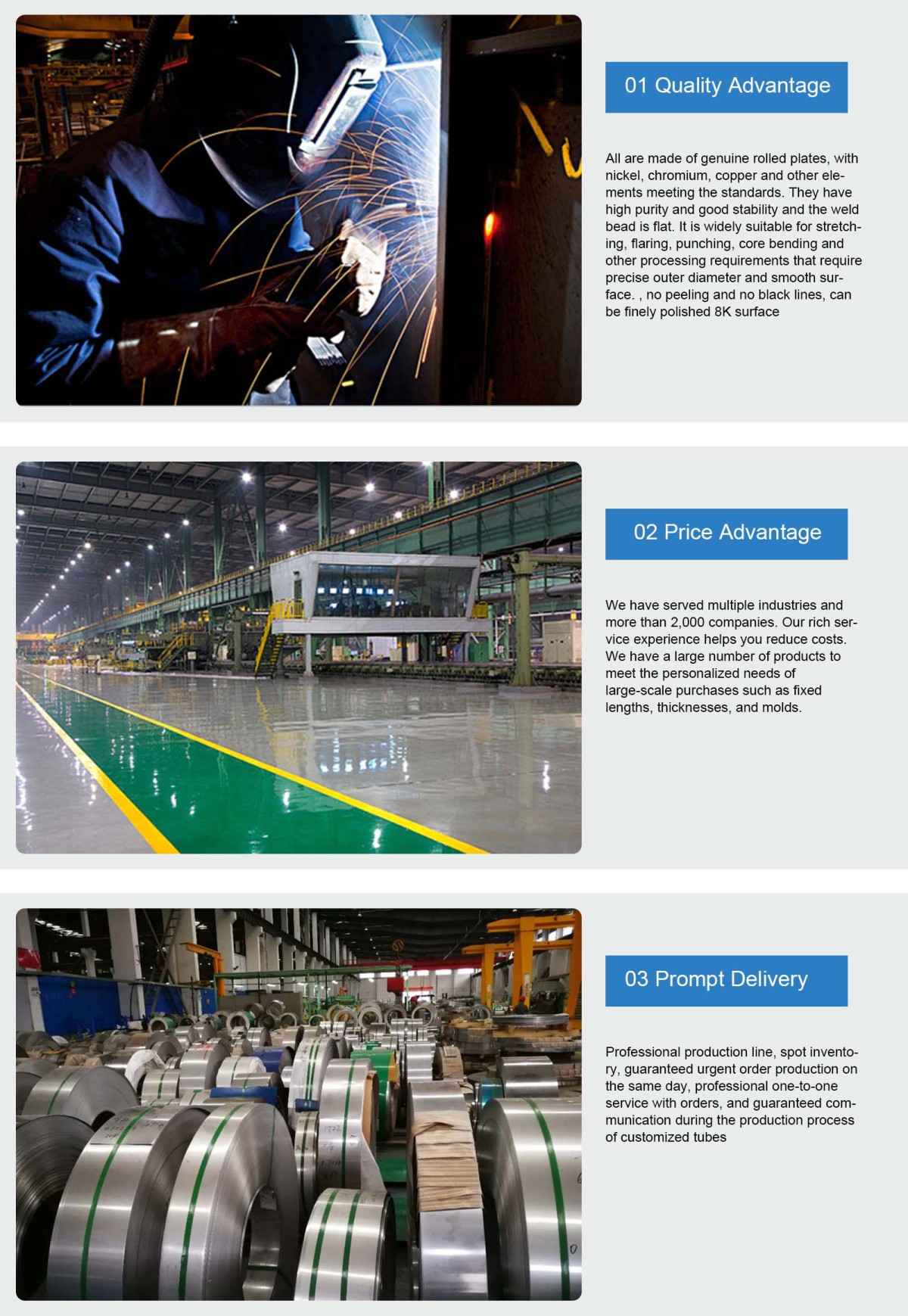

A: Quality first. In order to guarantee high quality for our products,

Modern always makes a serious inspection for all products and raw materials in strict procedure.

CONTACT US

Contact Us

Shandong PipeNil Metal Products Co., Ltd

Tel:+86 15763515130

E-mail: sales@pipenil.com

Address: Room 701, Building 8, Shangang Xintiandi, Industrial South Road, Jinan Area, China (Shandong) Pilot Free Trade Zone