PRODUCTS

Request A Quote

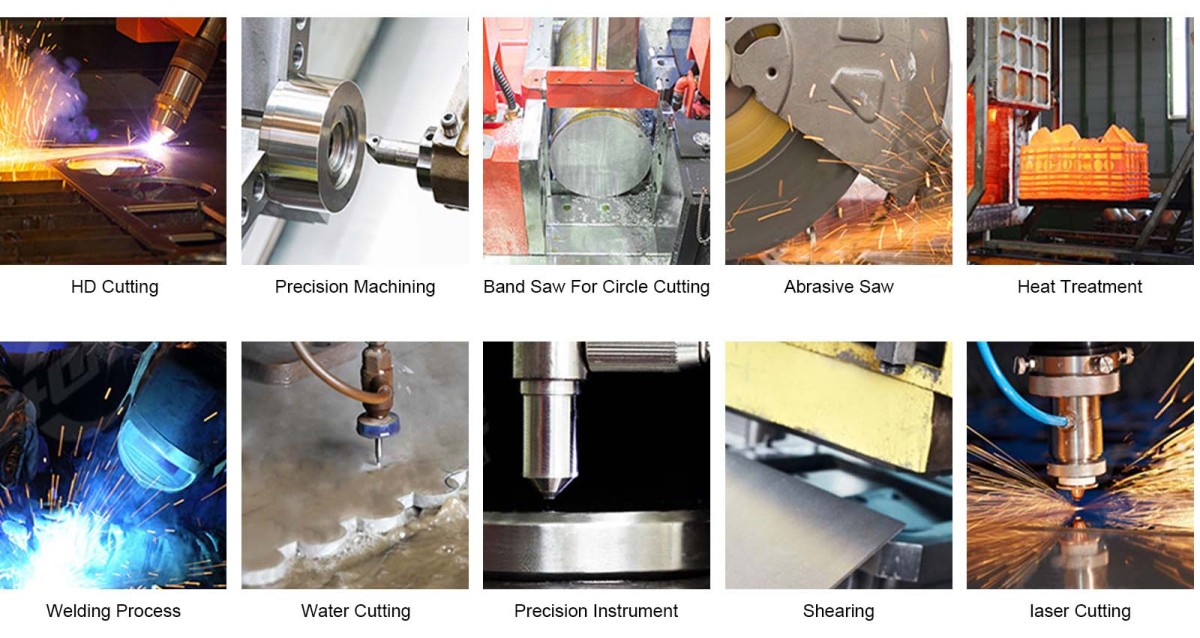

Alloy 926 is a multi-purpose material. Compared with the same series of alloys with 18% nickel content, the metallurgical stability is greatly improved. It has high resistance to pitting corrosion and crevice corrosion in halide media and acidic media containing H2S. performance, it can effectively resist chloride ion stress corrosion cracking in practical applications. Supply specifications: round steel, bars, plates, strips, pipes, fittings, flanges and forgings

chemical composition

Physical properties

Density:8.1g/cm3

Melting point:1320-1390C

Mechanical properties of alloy at room temperature (minimum value)

characteristic

1. It has high resistance to pitting corrosion and crevice corrosion in halide media and acidic media containing H2S.

2. It can effectively resist chloride ion stress corrosion cracking in practical applications.

3. Excellent resistance to various corrosions in normal gasification and reduction environments

4. The mechanical performance is greatly improved compared to Cronifer 1925 LC-Alloy 904 L

5. The metallurgical stability is greatly improved compared with the same series of alloys with 18% nickel content.

6. Have relevant certifications for pressure vessel manufacturing (VdTUV-196~400C and ASME certification)

Application scopeApplication areas

Alloy 926 is a versatile material that can be used in many industrial fields

1. Anti-prevention system, seawater purification system, hydraulic and perfusion pipeline system in marine engineering

2. Bleaching tank in cellulose pulp production

3. Polished rods in corrosive oil wells

4. Hose systems in marine engineering

5. Pipes, gas flow systems and other joints in acid gas production,

6. Components in flue gas desulfurization system

7. Evaporators, heat exchangers, filters, mixers, etc. in phosphoric acid production

8. Sulfuric acid separation and condensation system

9. Evaporator for concentrating and crystallizing salt

10. Condensation and piping systems in power plants using sewage cooling water

11. Containers for transporting corrosive chemicals

12. Production of organic derivatives using acidic chloride catalysts

13. Reverse osmosis desalination plant

RECOMMENDED PRODUCTS

FAQ

Q: Are you a manufacturer or trading company?

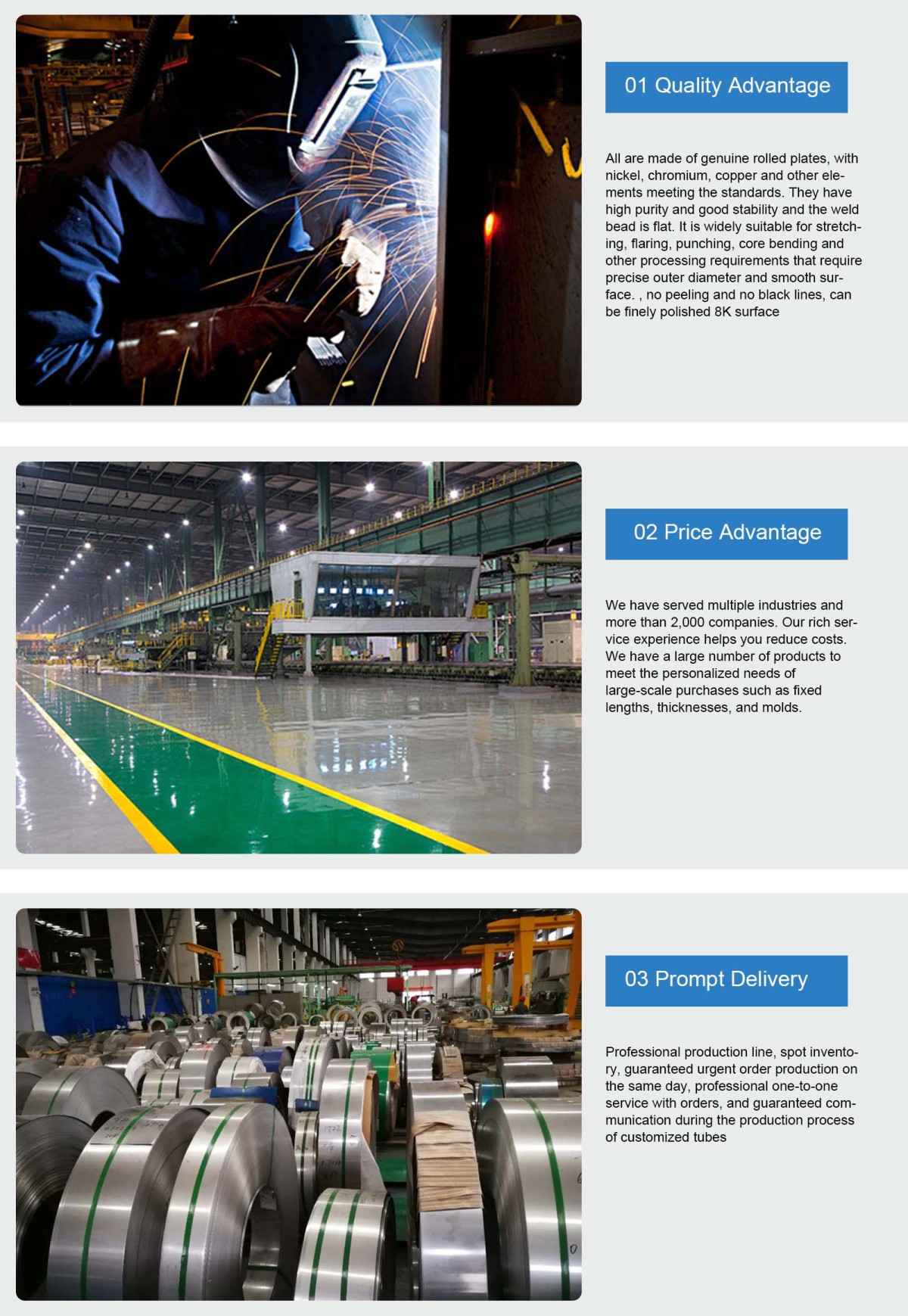

A: We are a specialized manufacturer.

Q: How about the delivery terms?

A: 1. Payment: T/T, Western Union, Paypal, 30% deposit in advance and balance before delivery.

2. Min. Order Quantity: 100KG, or as required.

3. Transportation: By express (DHL,TNT,FedEx),air,sea,and train.

Q: How about discount?

A: Price is based on products and order quantity.

Q: Do you accept sample order?

A: Yes sure, please contact us for details.

Q: How about your after-sales service?

A: As a professional steel exporter, we offer promote technology support for all problems and questions.

Besides, we accept goods return or replace for quality problem.

Q: How does your company control the quality?

A: Quality first. In order to guarantee high quality for our products,

Modern always makes a serious inspection for all products and raw materials in strict procedure.

CONTACT US

Contact Us

Shandong PipeNil Metal Products Co., Ltd

Tel:+86 15763515130

E-mail: sales@pipenil.com

Address: Room 701, Building 8, Shangang Xintiandi, Industrial South Road, Jinan Area, China (Shandong) Pilot Free Trade Zone