PRODUCTS

Request A Quote

800H is resistant to many corrosive media. Its high nickel content makes it very resistant to stress corrosion cracking in aqueous corrosive conditions. The high chromium content gives it better resistance to pitting and crevice corrosion cracking. This alloy has good corrosion resistance to nitric acid and organic acids, but has limited corrosion resistance in sulfuric acid and hydrochloric acid. Incoloy 800H(UNS N08810/WNr.1.4958)

Incoloy 800H chemical composition:

Physical properties of Incoloy 800H:

Density:8.0 g/cm3

Melting point:1350-1400C

The minimum mechanical properties of Incoloy 800H alloy at room temperature:

800H alloy has the following characteristics:

1. Excellent corrosion resistance in extremely high temperature aqueous media up to 500C

2. Very good resistance to stress corrosion

3. Good processability

Incoloy 800H metallographic structure: 800H has a face-centered cubic lattice structure. The extremely low carbon content and increased Ti:C ratio increase the structural stability and maximum resistance to sensitization and intergranular corrosion, 950° Low-temperature annealing around C ensures a fine-grained structure.

Corrosion resistance of Incoloy 800H::800H is resistant to corrosion by many corrosive media. Its high ballast content gives it good resistance to stress corrosion cracking in aqueous corrosion conditions. The high chromium content makes it more resistant to pitting corrosion and seam corrosion cracking. This alloy has good corrosion resistance to nitric acid and organic acids, but has limited corrosion resistance in sulfuric acid and hydrochloric acid. In addition to the possibility of pitting corrosion in friendly compounds, it has good corrosion resistance in oxidizing and non-oxidizing salts. Also has good corrosion resistance in water, steam and mixtures of steam, air and carbon dioxide

Incoloy 800H Application Scope Application areas include:

1. Nitric acid condenser - resistant to nitric acid corrosion

2. Steam heating tube-very good mechanical properties

3. Heating element tube has good mechanical properties

For applications up to 500°C, the alloy is supplied in the annealed condition.

RECOMMENDED PRODUCTS

FAQ

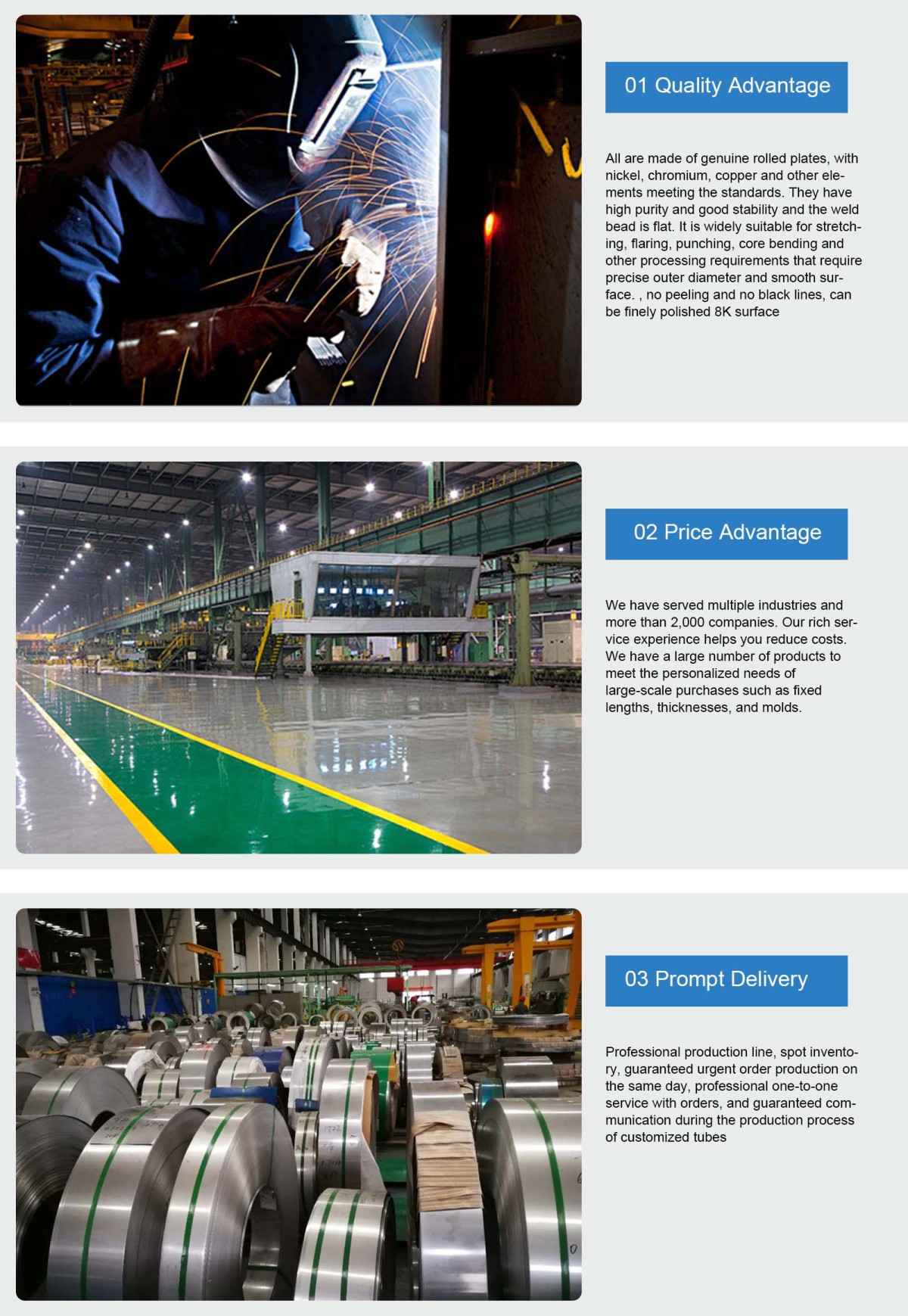

Q: Are you a manufacturer or trading company?

A: We are a specialized manufacturer.

Q: How about the delivery terms?

A: 1. Payment: T/T, Western Union, Paypal, 30% deposit in advance and balance before delivery.

2. Min. Order Quantity: 100KG, or as required.

3. Transportation: By express (DHL,TNT,FedEx),air,sea,and train.

Q: How about discount?

A: Price is based on products and order quantity.

Q: Do you accept sample order?

A: Yes sure, please contact us for details.

Q: How about your after-sales service?

A: As a professional steel exporter, we offer promote technology support for all problems and questions.

Besides, we accept goods return or replace for quality problem.

Q: How does your company control the quality?

A: Quality first. In order to guarantee high quality for our products,

Modern always makes a serious inspection for all products and raw materials in strict procedure.

CONTACT US

Contact Us

Shandong PipeNil Metal Products Co., Ltd

Tel:+86 15763515130

E-mail: sales@pipenil.com

Address: Room 701, Building 8, Shangang Xintiandi, Industrial South Road, Jinan Area, China (Shandong) Pilot Free Trade Zone