PRODUCTS

Request A Quote

Incoloy 800HT is a fully austenitic low-carbon iron-chromium alloy in the same series as Incoly 800. The diamond content in this alloy can be strictly controlled below 0.01%. Incoloy 800HT is resistant to corrosion in many corrosive media, and its high nickel content makes it highly resistant to stress corrosion cracking in aqueous corrosive conditions.

The high chromium content gives it better resistance to pitting and crevice corrosion cracking. This alloy has good resistance to nitric acid and organic acid corrosion, but its corrosion resistance in sulfuric acid and hydrochloric acid is limited. In addition to the possibility of pitting corrosion in halides, it has good corrosion resistance in oxidizing and non-oxidizing salts. Corrosion resistance.

It also has good corrosion resistance in water, steam and mixtures of steam, air and carbon dioxide. It is used in nitric acid condensers - resistant to nitric acid corrosion, steam heating tubes with good mechanical properties, heating element tubes with good mechanical properties, etc. For applications up to 500°C, the alloy is supplied in the annealed condition.

Incoloy800HT has the following features:

1. Excellent corrosion resistance in extremely high temperature aqueous media up to 500°C

2. Very good resistance to stress corrosion

3. Very good processability

Incoloy800HT grades and standards:

German brand:WNr.1.4876

DIN grade:X10NiCrAITi3220

French brand: Z8NC32.21

British brand:NA15

American brand: UNSNO8811

ISO grade: FeNi32Cr21AITi

ASTM:UNS N08811

Incoloy800HT chemical composition:

Incoloy800HT metallographic structure: Incoloy800HT alloy has a stable face-centered cubic structure. The chemical composition and appropriate heat treatment ensure that the corrosion resistance is not weakened by sensitization.

Incoloy800HT Corrosion Resistance: Incoloy800HT is a general engineering alloy that is resistant to acid and alkali metal corrosion in both oxidizing and reducing environments. The high nickel content makes the alloy effectively resistant to stress corrosion cracking and has good corrosion resistance in various media, such as sulfuric acid, phosphoric acid, nitric acid and organic acids, alkali metals such as sodium hydroxide, potassium hydroxide and hydrochloric acid solutions. The higher comprehensive performance of Incoloy800HT is demonstrated in nuclear combustion dissolvers with various corrosive media, such as sulfuric acid, nitric acid and sodium hydroxide, all processed in the same equipment

Scope of application: Incoloy800HT is widely used in various industrial fields where the operating temperature does not exceed 550C

Typical applications are:

1. Heating tubes, containers, baskets and chains used in sulfuric acid pickling factories

2. Seawater cooling heat exchanger, marine product pipeline system, acid gas environment pipeline.

3. Heat exchangers, evaporators, washing, dipping tubes, etc. in phosphoric acid production.

4. Air heat exchanger in petroleum refining

5. Food course

6. Chemical process

7. Flame-retardant alloys for high-pressure oxygen applications

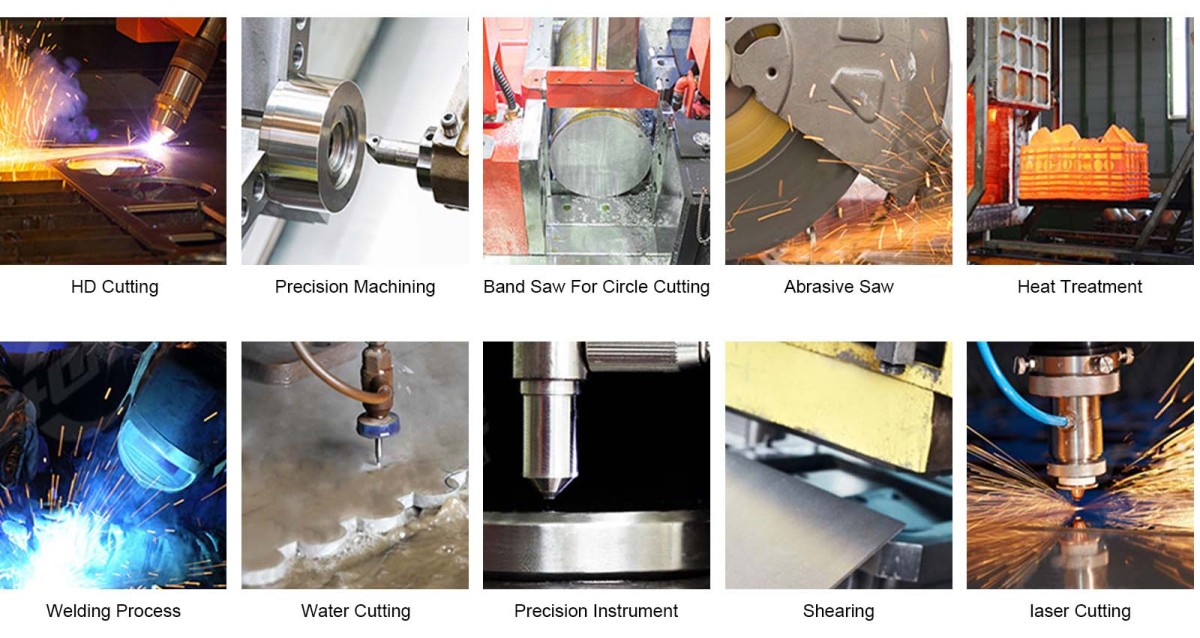

Incoloy 800H processing and heat treatment

Incoloy 800HT is suitable for hot and cold working, but due to its high strength, high-power processing equipment is required. Incoloy 800HT is suitable for welding with various convenient welding methods.

Incoloy800HT heating:

1. The workpiece should always be kept clean before and during heat treatment.

2. During the heat treatment process, do not come into contact with sulfur, phosphorus, lead and other low-melting point metals, otherwise the performance of the material will be damaged. Pay attention to removing contaminants such as marking paint, temperature indicating paint, color crayons, lubricating oil, fuel, etc.

3. The lower the sulfur content in the fuel, the better. The sulfur content in natural gas should be less than 0.1%, and the sulfur content in heavy oil should be less than 0.5%.

4. Considering the need for temperature control and maintenance of cleanliness, it is best to perform heat treatment in a vacuum furnace or gas protective furnace.

5. Heating can also be done in a box furnace or gas furnace, but the furnace gas must be clean and neutral to slightly oxidizing. Fluctuations between oxidizing and reducing properties of the furnace gas should be avoided. The heating flame cannot be burned directly. artifact.

RECOMMENDED PRODUCTS

FAQ

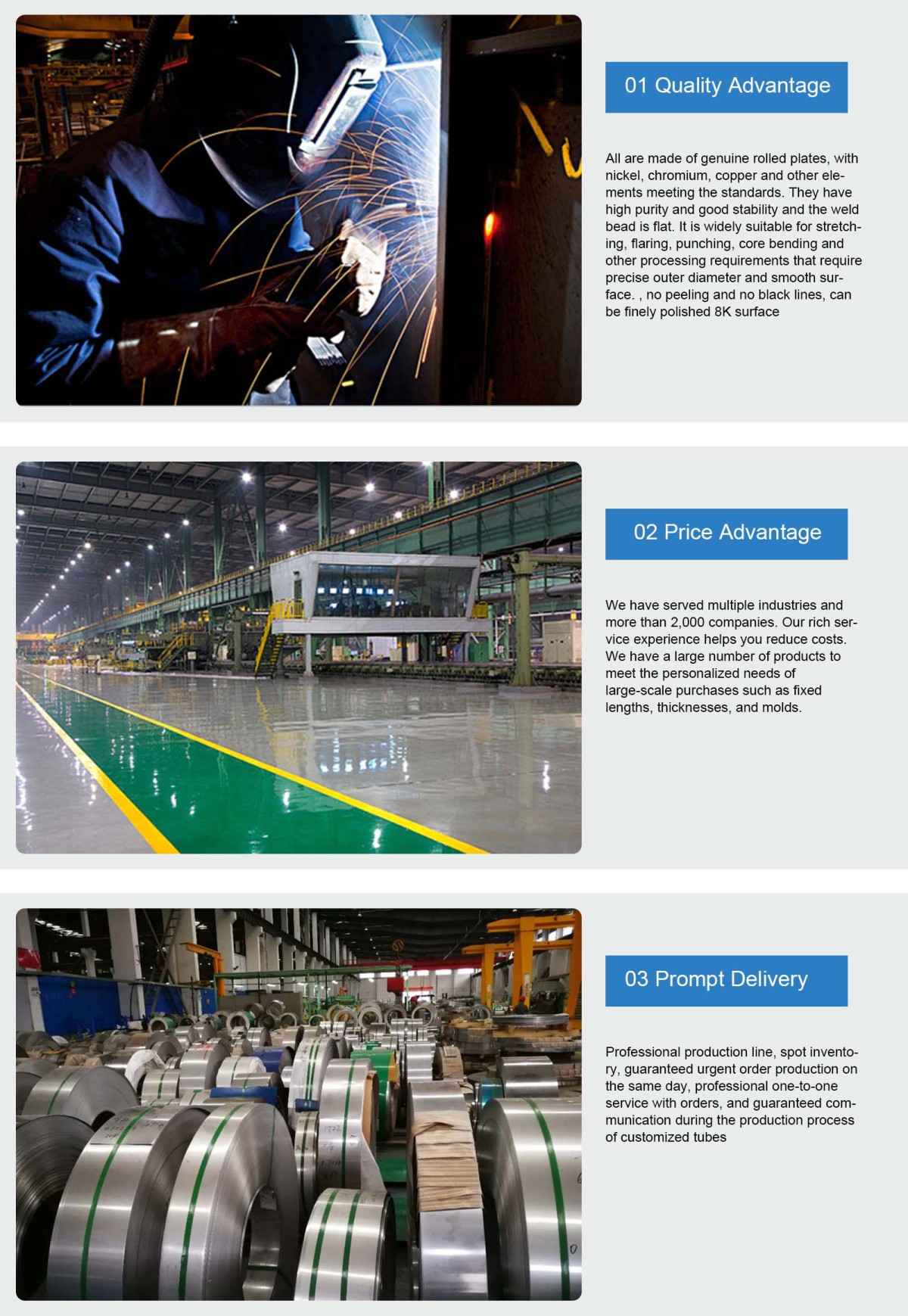

Q: Are you a manufacturer or trading company?

A: We are a specialized manufacturer.

Q: How about the delivery terms?

A: 1. Payment: T/T, Western Union, Paypal, 30% deposit in advance and balance before delivery.

2. Min. Order Quantity: 100KG, or as required.

3. Transportation: By express (DHL,TNT,FedEx),air,sea,and train.

Q: How about discount?

A: Price is based on products and order quantity.

Q: Do you accept sample order?

A: Yes sure, please contact us for details.

Q: How about your after-sales service?

A: As a professional steel exporter, we offer promote technology support for all problems and questions.

Besides, we accept goods return or replace for quality problem.

Q: How does your company control the quality?

A: Quality first. In order to guarantee high quality for our products,

Modern always makes a serious inspection for all products and raw materials in strict procedure.

CONTACT US

Contact Us

Shandong PipeNil Metal Products Co., Ltd

Tel:+86 15763515130

E-mail: sales@pipenil.com

Address: Room 701, Building 8, Shangang Xintiandi, Industrial South Road, Jinan Area, China (Shandong) Pilot Free Trade Zone